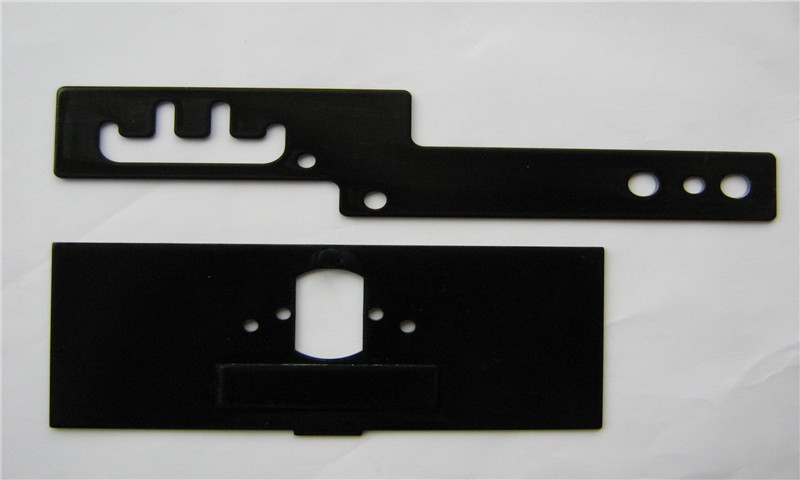

2711 High Corrosion Resistant Zinc-Iron Black Trivalent Chromating Process

2018-01-19

Code:2711

Name:2711 High Corrosion Resistant Zinc-Iron Black Trivalent Chromating Process

1.Contains no silver and produces a clear uniform jet-black. The color stability is perfect and avoids fading of silver-containing chromating processes after long-term stock.

2.Nanometer sealer is directly added to chromating solution and improves the corrosion resistance even higher than conventional hexavalent chromating. It can last 200 hours in ASTM B-117 neutral salt spraying test without white rusts and 720 hours without red rusts. The corrosion resistance and appearance keep the same after heat treatment. It’s especially good for auto part industry.

3.Easy for operation and maintenance. Stable solution and long life time.

4.The conversion film exhibits high-hardness and high resistance to scratch.

The abrasion resistance is superior to Hexavalent chromating processes.

5.Contains no Cr(Ⅵ) and oxidant, environmentally friendly products.It has been accepted by importers from European and America.

Make up: 2711A Zinc-Iron black trivalent chromating make up: 100-150ml/L; 2711BincZn-Iron black trivalent chromating corrective: 20-50ml/L.

consumption: 2711B Zinc-Iron black trivalent chromating corrective: 1.5-2L/10000dm2.; 2711C Zinc-Iron black trivalent chromating replenisher: 5-7L/10000dm2.