221 Bright Alkaline Cyanide-Free Zinc Plating Process

2017-12-05

Code:221

Name:221 Bright Alkaline Cyanide-Free Zinc Plating Process

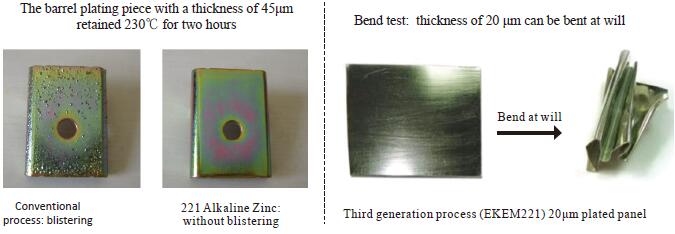

221 process is the newest cyanide-free zinc plating technology, It overcomes the problem of embrittlement even in mirror bright and thicker deposits. The metal distribution and the temperature tolerance of the electrolyte are more perfect .

①Mirror Bright Coating

221 Brightness is higher than the Cyanide Zinc Plating Process and Conventional Alkaline Zinc Plating Process, and comparable to Acid Zinc. Passivating without fogging haziness.

②Avoids Yellowing Problem Of Blue Chromate

221 Alkaline Zinc after blue chromate, the coating is deep blue, comparable to Acid Zinc.

③Not Hazy Of Yellow Trivalent Chromating

221 Alkaline Zinc coating is clear and transparent; the Cyanide Zinc Plating coating is tend to fogging be hazy.

④High Bright Deposit Without Embrittlement

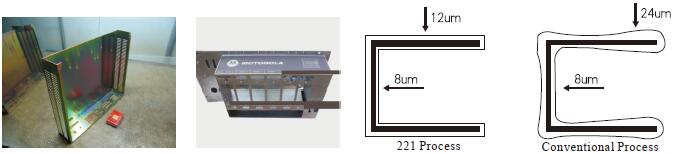

⑤High Throwing Power and Even Metal Distribution

High throwing power, and even thickness of coating, greatly saves the consumption of Zinc ingot, saving 25-40% than Acid Zinc, 15-30% than Cyanide Zinc Plating.

Left fig: the thickness of outer coating is 25μm, inner is no less than 17μm 221工艺

221 Process

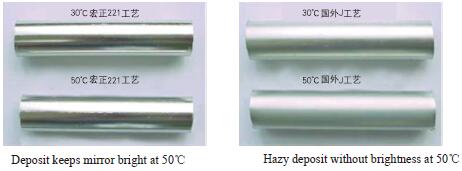

⑥ Tolerance to High Temperature

When the bath temperature is 50℃, the coating is still mirror brightness bright.

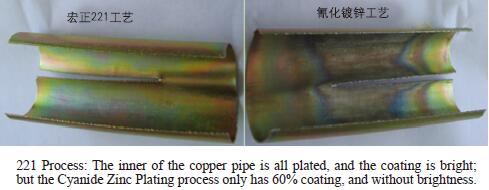

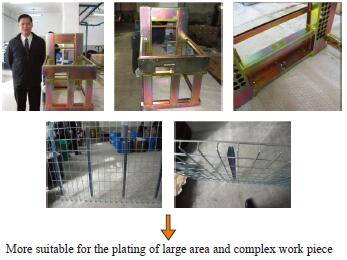

⑦ Excellent Covering Power

The covering power is superior to Cyanide Zinc Plating and Acid Zinc.

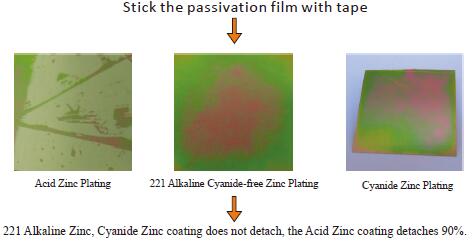

⑧Super Adhesion to Passivation Film

The adhesive force of 221 Alkaline Zinc coating is greater than Acid Zinc, and is comparable to Cyanide Zinc Plating.

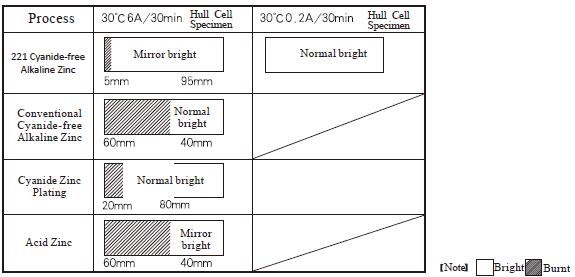

⑨Wide Current Operating Range

When the current is 6A in the Hull Cell, the whole specimen panel only has 0.5 cm burnt, when 0.2A, the specimen panel can be bright.

⑩Strong Impurity Tolerance

□The bath can be prepared with ordinary and tap water ,no need for 99% high purity alkaline hydroxide and pure water.

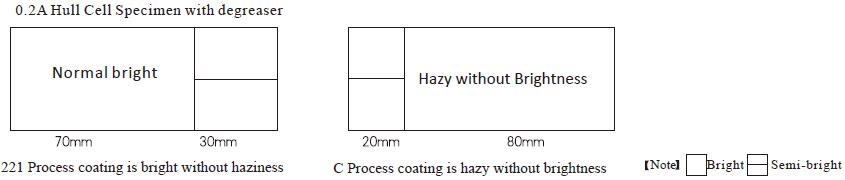

□Strong tolerance of impurity from pretreatment, the test is as follows:

Comments: It is better to carry out the pretreatment completely, and use high purity alkaline and pure water to prepare the cell bath.

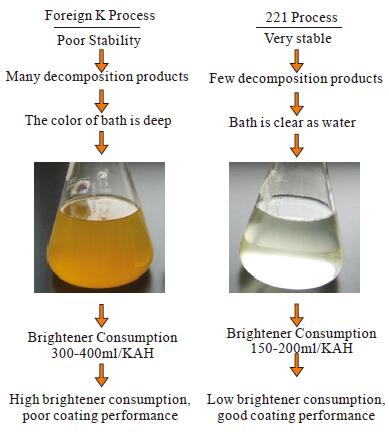

⑪Stable bath

⑫Key Points Of Maintenance

Make-up:

221 A brightener 5-25ml/L,

221B Carrier 0.5-1.5ml/L,

221C purifier 0.5-1.5ml/L.

Consumption:

221A brightener 100-200ml/KAH,

221B Carrier 20-70ml/KAH,

221C purifier 10-20ml/KAH.